The Problem of Car Production

The average car consists of around 30,000 parts. They are built up from many different resources that come from all over the world. These resources have to be mined and turned into raw materials. After that, they have to be manufactured into parts which are then turned into the components that form a rolling ton of metal, glass, rubber, and plastic.

At each stage of this process, a lot of energy is needed to process the parts and transport them all over the world. It is very difficult to put an exact number on the damage done to the environment from the production process, but generally, you can assume that for a car built in 2017, around 500kg of CO2 is emitted in the production process. And then I have not taken into account the water consumption, waste, and other factors of pollution. That is the equivalent of driving 3370km in a base model petrol 1.6l Volkswagen Golf (1).

A lot of attention goes to electric cars, and they will do a lot of good for the environment. But it seems like we look over the fact that we produce more cars each year (70 million in 2018) and that this is a big contributor to global warming (2). The most obvious solution to this problem is to make the production process more sustainable. Car companies are achieving really great results with this thanks to recycling. Between 2008 and 2018, the CO2 emissions of the production process went down with 24%. And similar results were achieved for other polluting factors (1). The problem is that these solutions can only help to a certain point because you will always have to use resources and energy to make a car, even when you take recycling into consideration. Also, it does not take into account the cost of transporting parts all over the world.

It sounds crazy that resources have to be mined from all over the world, transported, manufactured in different places and transported again. All to create a product with a super low profit margin. Why are we doing this?

Why Change Is Possible

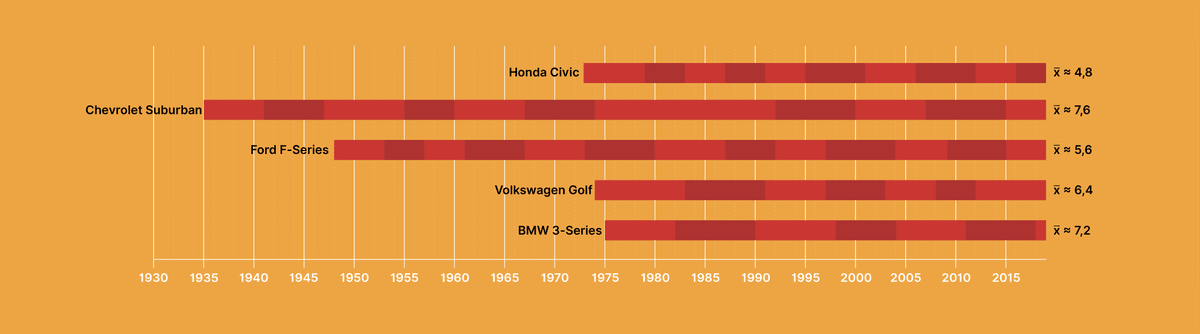

When a car company decides it is time for a new car model, they will spend around 4 years in development. After that, they plan to have the car in production for around 7 years. So every 7 years they plan a new generation (the 7 years include facelifts). The graph below shows how this number has largely stayed the same throughout time.

On the other hand, the average age of cars on the road has been steadily increasing, from around 7 years in 1977 to 11 years in 2017. According to IHS Automotive, the length of ownership has also increased from 3,5 years to 6 years between 2005 and 2015 (3). People are not buying as many new cars as before and they are holding on longer to their current ones. There are many reasons that can be attributed to this: socio-economic influences, the environment, the rise of other types of mobility, etc.

But a big factor is also that 30 years ago, the difference between two model generations was huge. The build quality was much better, the engine was more powerful, the car was much more comfortable, etc. Today, we have reached a point where the basic design and layout of most of the components of a car have found an optimum.

A common complaint I hear is that cars all look the same. In the early days of the car, manufacturers tried out every possible way to improve their products and get ahead of the competition. What if cars have jet engines? What if cars have three front seats, what if we use a joystick as a steering wheel? In the last 25 years, car design has found its optimum. Today, even the base model Volkswagen Golf is a perfect car. It is fast enough, it is reliable, it has amazing build quality, it is comfortable, the brakes, gearbox, and other mechanical components will survive pretty much all the car will encounter, it is safe, etc.

This means that a new model generation that is introduced today will not be the same big step forward as a new model introduction 30 years ago. And it seems that car buyers are realizing this. So why can’t car manufacturers respond to this need and create cars that stay modern for much longer?

How Designers Can Solve This Problem

Developing a new model from scratch every couple of years seems like a big waste of time and money for car companies. If I have owned a car for a couple of years, I might look at other cars and see that the cluster screen in my car is a bit outdated. Other cars have better cluster screens that show much more useful information. Maybe, the seat upholstery in my car is worn out a little and has stains on it. These two points are enough for me to start considering a new car. Even though every other component of my car is still in great shape.

What if, instead of going to the dealership and trading it in for a new one, only the cluster screen is replaced and the seats are re-upholstered. My car would be good to go another couple of years and it would save all the needless effort to create a brand new car. Cars can be specially designed to allow for this more modular way of thinking.

What I am proposing is a very big challenge. It will require a change in attitude from customers and car companies. I think designers can help a lot with this by designing cars that are less bound to trends and use longer-lasting materials.

It takes around 4 years to develop a new model. After the launch, a manufacturer aims to keep it into production for 7 years. That means that if a car company starts today with a new model, it will have to imagine what customers want in 2030 and what the world will look like then. It is a big challenge for designers but it is not impossible because it has been done before. Take the exterior design of the BMW i3 for example. This car was launched in 2013, and it has received very minimal facelifts. Aside from the fact if you like it or not, it is undeniable that it still looks very modern. The same goes for many other cars, like the Tesla Model S, and Fiat 500. I think most of these models will still look good even in a couple of years.

So from a design perspective, making cars last longer is definitely possible. But up until now, I have assumed that cars would get a little bit better with each generation but not change drastically. I am sure you have already thought about the future and how the cars will go through three big changes: in-car technology, electrification, and autonomous driving. It sounds unrealistic to design a car today in such a way that it will stay modern through all these transformations, but it is possible. The BMW i3 of the future can drive itself, it will have a longer range, and it will have better in-car technology, but the rest will not change dramatically. It is possible to take these changes into account today.

1. In-Car Technology

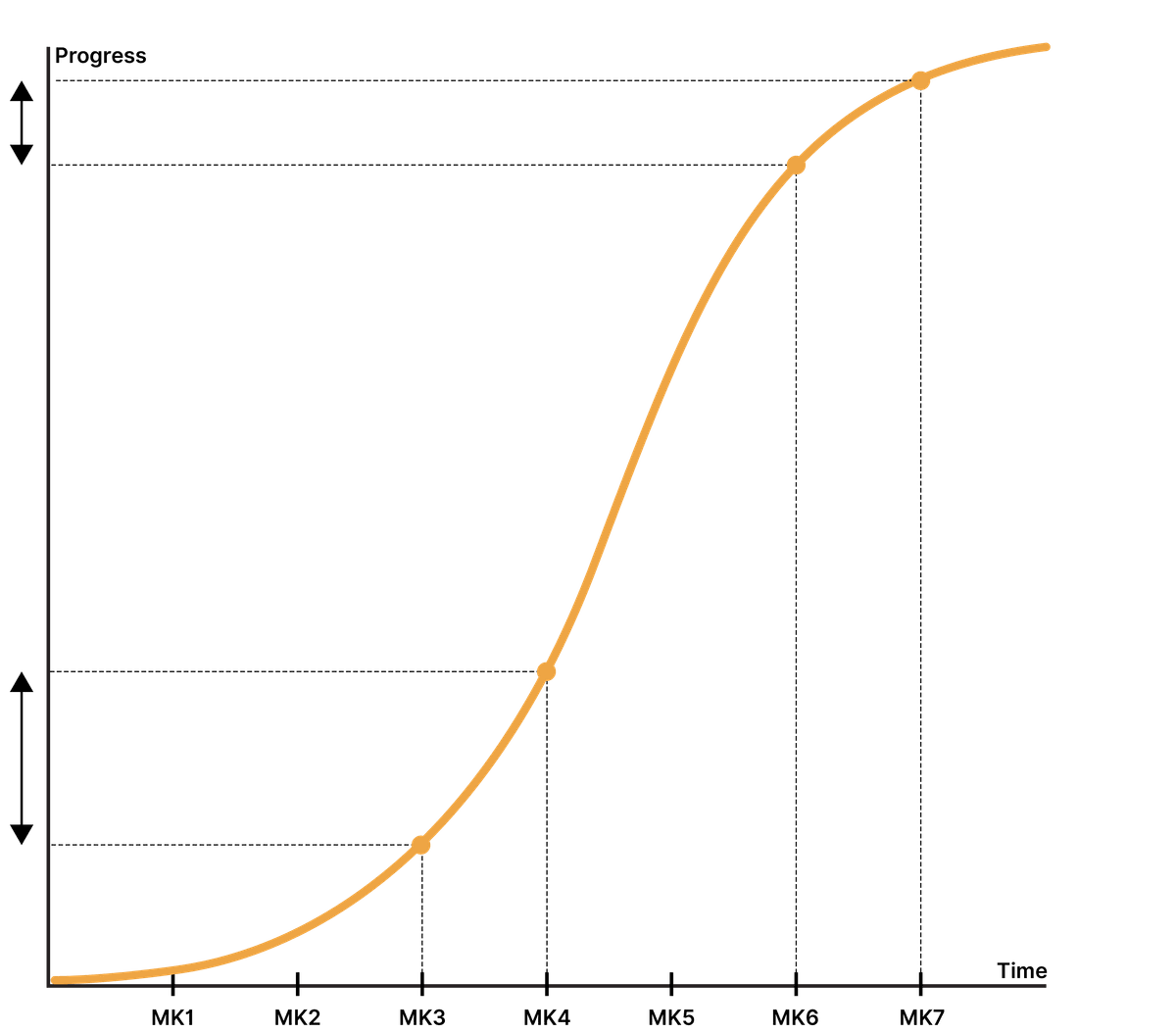

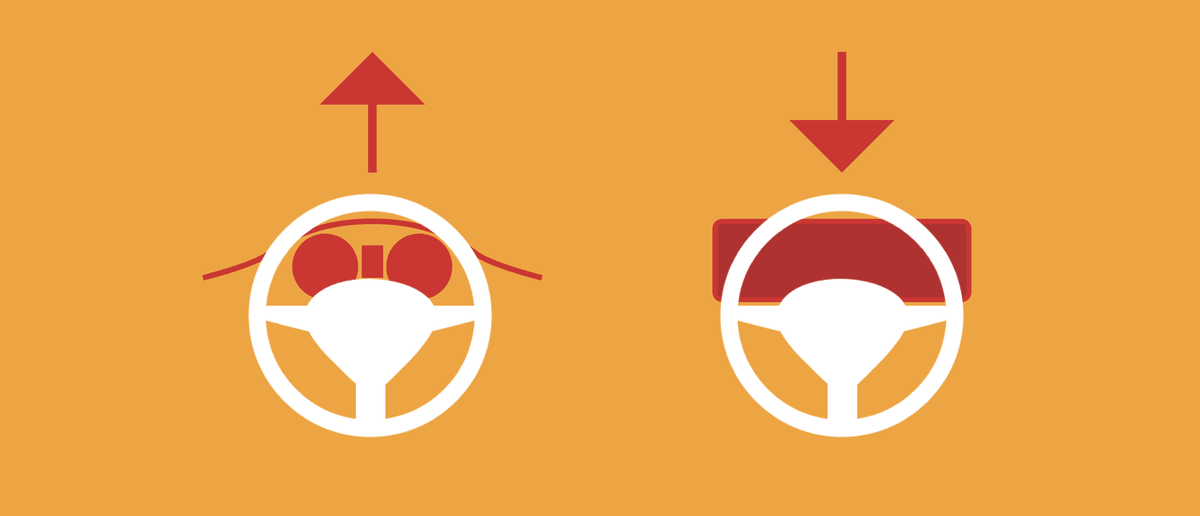

The capabilities of technology are increasing exponentially. As we saw, car companies think in production cycles of 7 years but because progress is so fast, products like smartphones have production cycles of around 1 year. To put that into perspective, the previous generation Volkswagen Golf (MK6) was launched around the same time as the first generation iPhone. Now think of the difference between the first generation iPhone and the iPhone 5, and compare it to the difference between the VW Golf MK6 and MK7 which have similar release dates. How can designers possibly know what technology will be available in 10 years? Of course they can’t know it, but they can anticipate big trends and they can design for flexibility.

Hardware like screens and computing power have become very good so today it is possible to plan multiple years ahead in that field by fitting good hardware. Alternatively, interiors can be designed in such a way that the screens can easily be replaced by better ones after a couple of years. Or they might even be replaced by smartphones and tablets because they are extremely powerful nowadays and people regularly update their devices. Software on the other hand still changes very often. But over-the-air updates can solve this problem and keep the interface modern for a very long time.

The Tesla Model S is a great example of this because it was launched in 2012. By fitting the car with good hardware (a big screen with great graphics performance), and wireless internet connectivity which allows for updates, today, it is still the market leader in that field.

2. Electrification

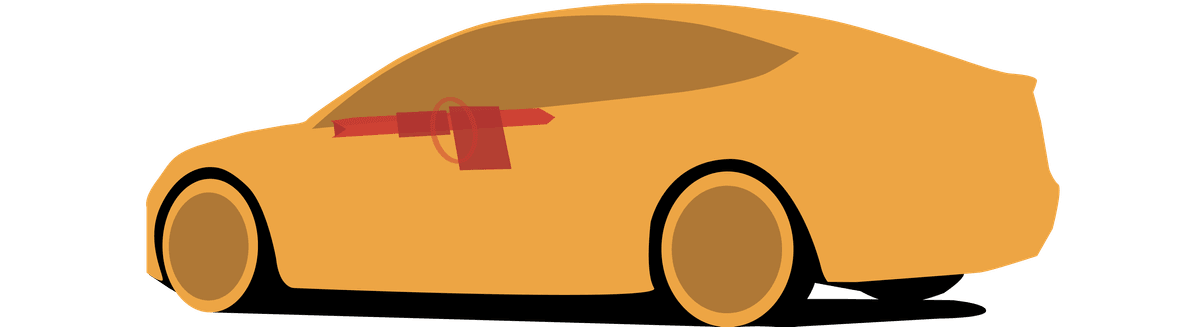

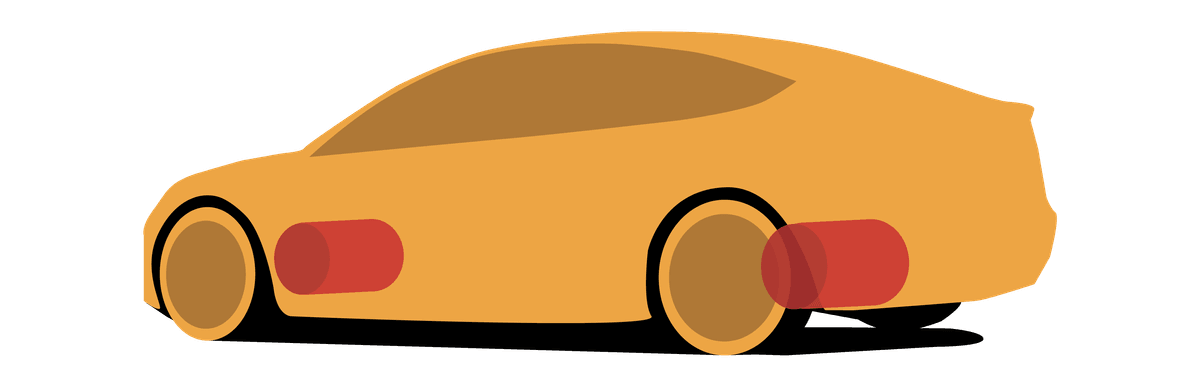

Electric cars are the future. It is only a matter of time before battery technology is good and affordable enough to match the qualities of combustion engines. At that point, the great majority will switch to electric cars because of the financial and environmental benefits. So the ideas I discuss here will not work for cars with internal combustion engines because most of them will be obsolete in 10 years. Electric cars, on the other hand, fit perfectly to this idea. In contrast to petrol engines, most of the steps forward in innovation are in battery technology and not in drivetrain technology. So cars can be engineered to have modular battery packs that can be upgraded when there are significant improvements. Cars can be designed in such a way that the battery pack is easily removable and replaceable.

3. Autonomous Driving

Of the three big changes, Autonomous driving is the hardest to plan for, but not impossible. With each car company and other players working hard to be the first, each company mentions different deadlines for full autonomy ranging from 2020 to 2050. Next to that, car companies are still exploring different kinds of autonomous driving technology so it is difficult to know what hardware they will use. But even here it is possible to plan for the long term. Again there are two fields of improvement: software, which can be done with over-the-air updates, and hardware.

A solution is to install all the hardware already in each car. Then, when the software is good enough, you can release a software update to the entire fleet. This is what Tesla is doing and it is mostly possible because they are using a pretty basic setup with cameras, radar, and ultrasonic sensors which are all quite small. Alternatively, car companies using bigger, bulky sensors like Lidar, can mount them in such a way that they can be replaced later when better sensors are available.

Why Would Car Companies Invest in Increasing the Lifespan of Their Cars?

Car manufacturers are known to be quite risk averse and conventional. So why would they ever try to create cars that last longer so that they basically sell fewer The first incentive is that it is super expensive to produce a car today. Designing cars in a modular way will reduce costs. Car manufacturers won’t have to keep big factories running around the clock, they won’t have to continuously ship parts all over the world, they won’t have to engineer a completely new car every 7 years, etc. A second reason is that more and more customers are simply not interested in buying new cars anymore and the reputation of the car is going down every year. Cars are becoming more expensive, they ruin cities, they are polluting, dangerous, and expensive. Especially the younger generations are losing interest in cars. There are more and more startups exploring other types of mobility and Uber is currently already valued higher than Ford.

If you combine these first two reasons, any car executive would be a bit nervous. It is clear that car companies cannot continue on their current path. Fortunately, there have already been some changes in the industry already with car brands reducing the number of models they have on offer and exploring new business models based on subscriptions. It is still disappointing to see that none of these companies seem to think about the lifespan of their products. We have seen that car companies need to change to satisfy new customer demands and that a modular car can reduce costs, but how can car companies earn money with this?

The bright side is that subscription-based business models do allow for these changes to happen. There is a way to use a service-based model that will push car manufacturers to develop longer lasting cars. They can be based on the principles of the circular economy. The customer would pay a monthly fee for ‘transportation’ while the car company takes care of all the rest. Here is an example. Maybe I like Volvo because I value safety. So I am going to pay x amount per month for a Volvo subscription that offers me ‘transportation’. Volvo fills in for me what that means. It could mean a big SUV for when I go on holiday, or it could mean a small city car for my daily commute. Volvo takes care of everything. They will pay for all the costs, repairs, charging, updates, winter tires, etc. Since all the costs that would usually go to the owner of the car, now go to Volvo, it pushes them to create cars that last long, are economical, and easy to repair or upgrade. Another possibility is that the environmental cost is factored in into the price of the car or subscription via a tax. Car companies that create cars in an environmentally friendly way can offer cheaper products. This will push them to develop longer lasting and more economical cars. This kind of tax is increasing in popularity in politics and with the problem of global warming getting more critical every year, a tax like this could be implemented in the short term by progressive countries.

There are plenty of other solutions to this problem. In the end, I think it is mostly up to the designers and engineers at car companies to start this movement. I hope the people working for car companies can take advantage of the upcoming changes in this industry to lead the way in this.

(1) ACEA, 2018

(2) Statista, 2019

(3) IHS, 2015

Get notified of new posts

Don't worry, I won't spam you with anything else